Unraveling the Earth: The Difference Between Geonet and Geogrid

In the realm of geotechnical engineering, materials like geonets and geogrids play pivotal roles in reinforcing soil, enhancing erosion control, and facilitating drainage. Geogrids, in particular, are plastics formed in a wide open, regular netlike structure, purpose-developed for the reinforcement of soil. This specific design allows them to interlock with soil particles, significantly enhancing the soil’s stability and load-bearing capacity. Despite their similar applications, these materials possess distinct characteristics and functionalities. This article delves into the nuances between geonets and geogrids, exploring their definitions, purposes, types, and lifespans, providing a comprehensive understanding for professionals and enthusiasts alike.

What is the difference between a Geonet and a Geogrid?

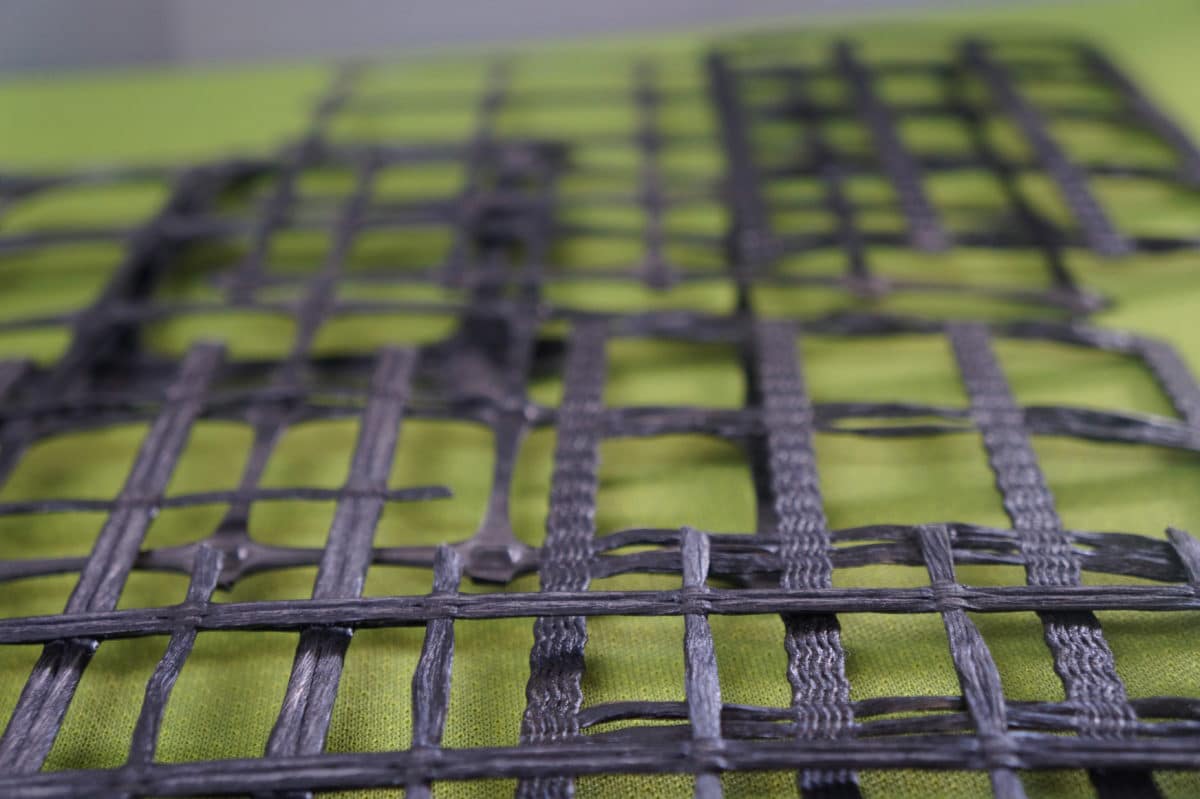

Geonets and geogrids, while both used in geotechnical and environmental engineering projects, differ primarily in their structure and intended use. A geonet is a net-like material made from polyethylene or other polymers, designed primarily for drainage purposes. It has a biplanar or triplanar structure, allowing for efficient water flow across its surface. In contrast, the geocell is a deep, three-dimensional mesh structure, offering a different approach to soil stabilization and erosion control.

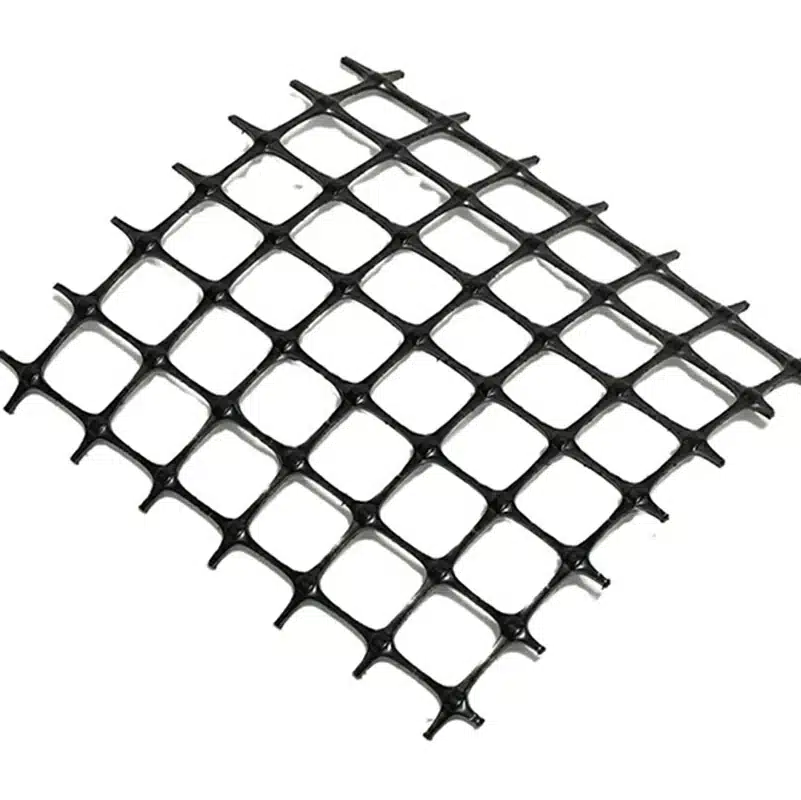

On the other hand, a geogrid is a geosynthetic material with a grid-like structure, typically two-dimensional, used mainly for soil reinforcement. Geogrids are made from high-strength polymers and are designed to interlock with soil and aggregate particles, thereby increasing the strength and stability of the soil structure. This two-dimensional nature of geogrids contrasts with the three-dimensional structure of geocells, yet both are crucial in their respective roles. Unlike geonets, geogrids are available in various types, each tailored for specific reinforcement applications such as retaining walls, roadbeds, and embankments, highlighting the versatility and specific applications of these geosynthetic materials in improving infrastructure and environmental projects.

What is the purpose of a Geogrid?

The primary purpose of a geogrid is soil reinforcement, specifically engineered to reinforce soils and similar materials. It provides tensile strength to soil, enhancing its load-bearing capacity. This reinforcement mechanism helps prevent soil erosion, supports the construction of retaining walls, embankments, and roadways, and improves the overall stability of the soil structure. By distributing loads over a wider area, geogrids can significantly extend the lifespan of various civil engineering projects, making them an indispensable tool in the field.

What are the three types of Geogrid?

Geogrids can be categorized into several types based on their manufacturing process and the direction of their strength, including Uniaxial, Biaxial, Triaxial (Triax®), and Geogrid-Geotextile Composites:

Uniaxial Geogrids: These are designed to provide strength in one direction and are commonly used in retaining wall and slope stabilization projects. Their specific structure is ideal for applications where support is needed predominantly in a single direction.

Biaxial Geogrids: Offering strength in two directions, biaxial geogrids are often utilized in roadway and pavement applications, where equal distribution of load in both directions is crucial. This bidirectional strength is essential for ensuring the stability and durability of the paved surfaces.

Triaxial Geogrids (Triax®): With strength distributed in three directions, triaxial geogrids provide a more uniform reinforcement, making them suitable for a wide range of applications, including base reinforcement for roads, railways, and foundations. Their triaxial structure offers enhanced stability and support compared to uniaxial and biaxial types.

Geogrid-Geotextile Composites: These innovative materials combine the reinforcement capabilities of geogrids with the separation and filtration functions of geotextiles. They are particularly useful in complex engineering projects where both reinforcement and drainage/separation are required.

This classification underscores the versatility of geogrids in addressing various geotechnical engineering needs, from simple reinforcement to complex stabilization and drainage requirements.

What is the lifespan of a Geogrid?

The lifespan of a geogrid can vary significantly depending on the material composition, environmental conditions, and the specific application it is used for. Generally, high-quality geogrids made from durable polymers are designed to last for over 100 years under optimal conditions. However, exposure to UV light, chemicals, and physical damage can reduce their lifespan. Proper installation and protection from direct sunlight and chemicals can help maximize the longevity of geogrids in geotechnical applications.

Understanding the difference between geonets and geogrids is crucial for professionals in geotechnical engineering and related fields. While both materials serve to improve soil stability and control erosion, their specific applications, structures, and functionalities set them apart. Geonets are primarily used for drainage, whereas geogrids are essential for soil reinforcement, available in various types to suit different engineering needs. Remarkably, geogrids have a potential lifespan of about 100 years, representing a long-term solution for enhancing the durability and stability of civil engineering projects. This impressive longevity underscores the value of geogrids in providing sustainable, effective reinforcement over time.

Comments

Post a Comment