Road Reinforcement: The Role of Geocell in Modern Road Construction

As road infrastructure continues to evolve, engineers and construction professionals are constantly seeking innovative solutions to enhance road durability and performance. One such advancement is the use of geocells in road reinforcement. This article explores the concept of geocells, and their application in road construction, and addresses common questions regarding their usage, gravel size, weld spacing, and installation process.

What is Geocell in Road Construction?

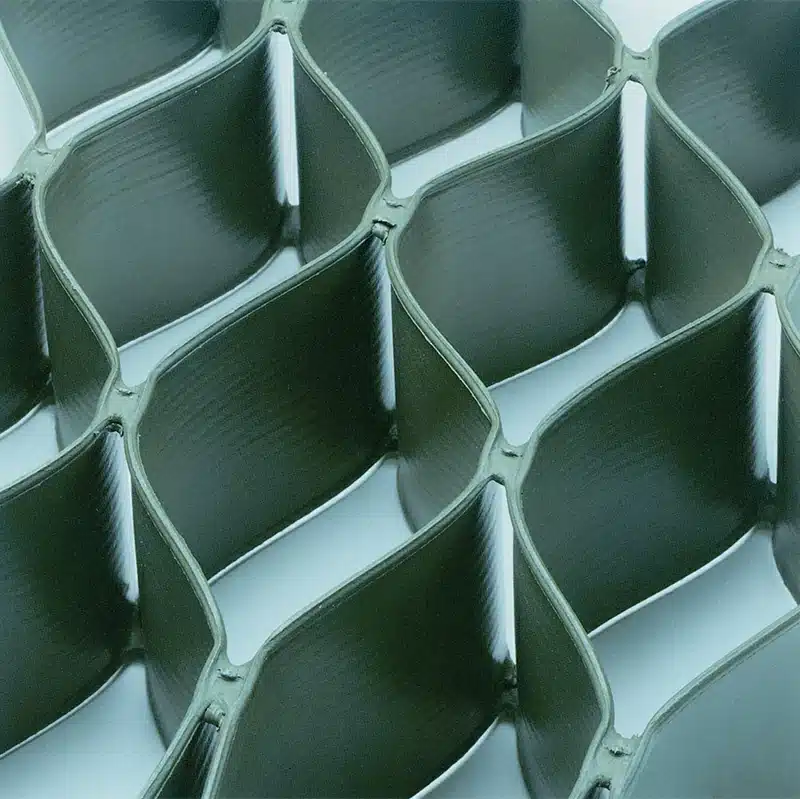

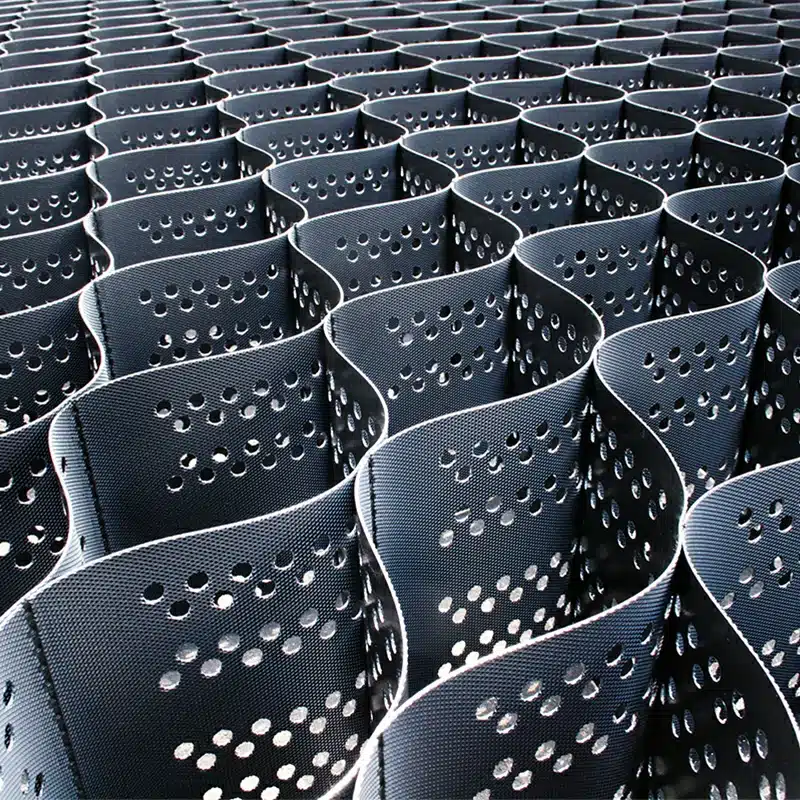

Geocells are three-dimensional, honeycomb-like structures made from high-density polyethylene (HDPE) or other polymer materials. These structures form a three-dimensional cellular structure that can be filled with soil, gravel, or other materials to stabilize steep slopes and prevent erosion. They are used in civil engineering to provide structural reinforcement and improve the load-bearing capacity of soils and aggregate materials. In road construction, geocells are laid down on a prepared subgrade and filled with granular materials like gravel or sand. This setup helps to distribute loads more evenly, reduce the deformation of the road surface, and prevent soil erosion. The cellular confinement system created by geocells also minimizes the movement of infill materials, leading to a more stable and durable road foundation.

What Size Gravel for Geocell?

The choice of gravel size for filling geocells is crucial for optimal performance. Typically, the recommended gravel size ranges from 3/8″ – 3/4″ (approximately 20mm to 50mm). This size ensures adequate compaction within the cells and provides sufficient interlocking to maintain stability. Smaller gravel sizes can lead to poor drainage and potential clogging, while excessively large gravel can cause issues with proper cell confinement. Using well-graded gravel with a mix of particle sizes within the recommended range can further enhance the load distribution and overall effectiveness of the geocell system.

What is the Weld Spacing for Geocell?

Weld spacing in geocells refers to the distance between the individual weld points that connect the strips of the polymer material, forming the honeycomb structure. Standard weld spacing for geocells used in road construction is typically around 14.0 in ± 0.12 in (355 ± 3 mm). This spacing is designed to balance flexibility and strength, allowing the geocell to conform to the ground’s contours while maintaining its structural integrity. Proper weld spacing is essential to ensure the geocell can effectively distribute loads and withstand the stresses imposed by traffic and environmental factors.

How to Install Geocell?

Installing geocell for road reinforcement involves several key steps:

- Site Preparation: Begin by preparing the subgrade. Ensure it is level, compact, and free of debris. This foundational layer should be stable to support the geocell and infill materials. Once your base is complete, you’re ready to add geocell to your project.

- Geocell Deployment: To add geocell, first trim the material to fit the area properly. Next, lay the geocell across the excavated area and secure it with stakes. To separate geocells from other ground layers, geotextile fabric can be used. Secure the edges using stakes or other anchoring methods to prevent movement during infill placement.

- Infill Placement: Fill the geocell with the appropriate gravel size, ensuring even distribution across all cells. Overfill slightly to account for compaction. Compaction Compact the infill material using a vibrating plate compactor or similar equipment. This step is crucial for achieving maximum density and stability.

- Surface Layer: Depending on the road design, add additional layers of gravel or other paving materials on top of the compacted geocell to complete the road structure.

Proper installation is key to maximizing the performance benefits of geocells in road construction.

Geocells are a vital component in modern road reinforcement, offering enhanced load distribution, stability, and erosion control. Understanding the correct gravel size, weld spacing, and installation process is essential for leveraging the full benefits of geocell technology. By incorporating geocells into road construction, engineers can create more durable and resilient roadways capable of withstanding the demands of heavy traffic and adverse environmental conditions.

Comments

Post a Comment