The Importance of HDPE Geomembrane in Geosynthetics Applications

When it comes to geosynthetics, HDPE geomembrane plays a vital role in a variety of civil engineering and environmental projects. As a durable, flexible, and reliable material, HDPE geomembrane provides significant advantages in applications ranging from landfills to water containment. In this article, we’ll dive deeper into the uses and benefits of this essential material.

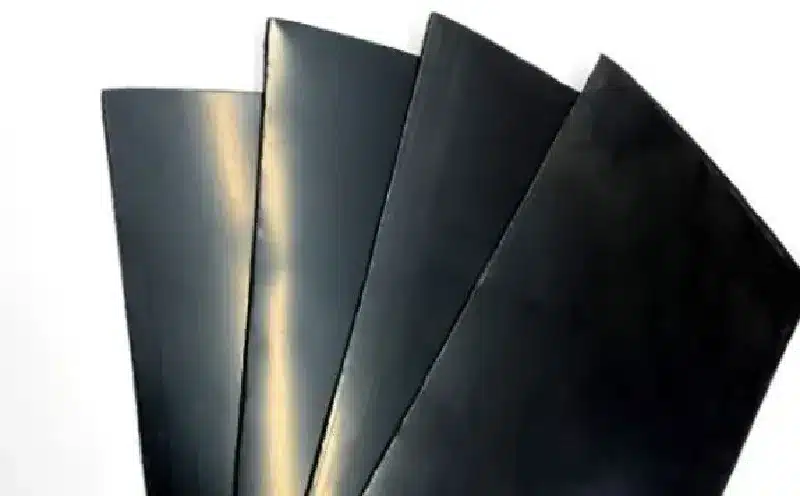

What is an HDPE geomembrane?v

An HDPE geomembrane (High-Density Polyethylene geomembrane) is a synthetic membrane made from polyethylene resin. Its primary function is to act as a barrier to prevent the passage of liquids, gases, or contaminants. Commonly used in environmental and civil engineering projects, it is known for its high chemical resistance, tensile strength, and excellent durability. The material is typically used in applications such as landfill liners, water reservoirs, and waste containment systems, where it serves to protect the environment from leakage or contamination.

What are the main benefits of using HDPE geomembrane in construction projects?

HDPE geomembrane offers several advantages that make it a top choice in the geosynthetics industry. Some key benefits include:

- Durability: HDPE is resistant to UV rays, chemical exposure, and extreme temperatures, ensuring long-term performance.

- Leak Prevention: Its impermeability makes it an ideal solution for containment systems, preventing water or waste leakage into surrounding soil or groundwater.

- Cost-Effectiveness: While the initial installation can be costly, the longevity and low maintenance requirements of HDPE geomembranes make them a cost-effective solution over time.

How is an HDPE geomembrane installed in construction projects?

The installation of HDPE geomembrane involves several steps to ensure proper function and longevity. First, the site is prepared by leveling the ground and ensuring a smooth surface. The geomembrane is then unrolled and placed over the prepared surface. Special welding techniques, such as extrusion or hot wedge welding, are used to join the seams and ensure airtight seals. The membrane is also often anchored at the edges to prevent movement during installation and over time. After installation, quality control tests are conducted to verify the integrity of the seams and the overall coverage.

In which industries is HDPE geomembrane commonly used?

HDPE geomembrane is used in a wide variety of industries where containment and environmental protection are key. Some common industries and applications include:

- Landfill Construction: Used as a liner to prevent leachate from contaminating surrounding soil and groundwater.

- Water Management: Applied in reservoirs, ponds, and canals to prevent water loss due to seepage.

- Mining Industry: Used in heap leach pads and tailing ponds to contain hazardous materials and chemicals.

- Agriculture: Helps to line ponds for irrigation or maintain water tables in agricultural fields.

In summary, HDPE geomembrane is a versatile and reliable geosynthetic material with a range of applications. Its chemical resistance, durability, and cost-effectiveness make it an invaluable asset in various industries that require secure containment solutions.

Comments

Post a Comment