Understanding Geomembrane Liners: Key Features and Applications in Geosynthetics

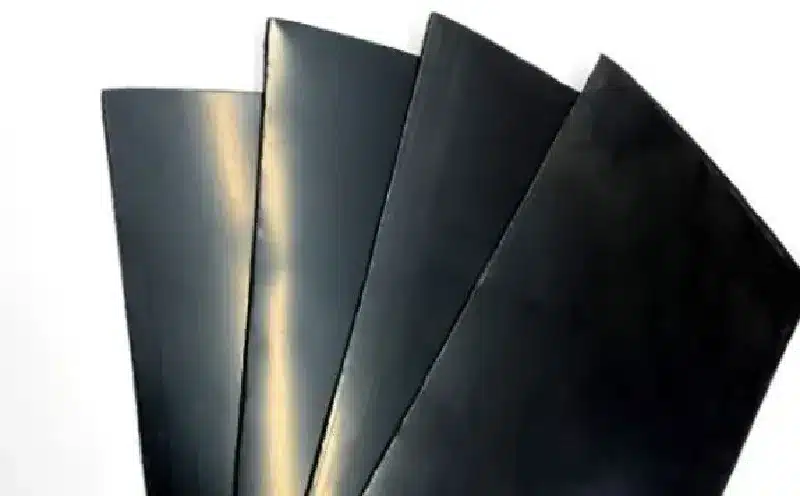

Geomembrane liners are crucial components in the field of geosynthetics, playing a pivotal role in various environmental and engineering applications. These synthetic sheets that are used to control the movement of fluids in man-made structures, typically made from durable polymeric materials, offer versatile solutions for containment, protection, and management of resources and environments.

What are Geomembrane Liners and How Are They Used?

Geomembrane liners are impermeable sheets manufactured from polymers like high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM). They are engineered to control fluid migration in diverse applications such as landfill containment, mining operations, and water conservation projects. These liners act as barriers, preventing seepage and contamination of soil and groundwater.

What are the Key Advantages of Geomembrane Liners?

Geomembrane liners offer several advantages over traditional materials like concrete or clay. They are lightweight, flexible, and easy to install over large areas, reducing construction time and costs. Their impermeability ensures effective containment of liquids and gases, minimizing environmental impact and enhancing operational safety. Additionally, they exhibit excellent chemical resistance, prolonging their lifespan even in harsh conditions.

Where are Geomembrane Liners Typically Used?

Geomembrane liners find extensive application in diverse sectors. Environmental engineers line landfills to prevent leachate from contaminating groundwater. In mining, they serve as tailings pond liners, protecting soil and water resources from toxic chemicals. In agriculture, they facilitate efficient water storage in reservoirs and irrigation ponds. They also play a crucial role in infrastructure projects such as canal lining and tunnel waterproofing.

How are Geomembrane Liners Designed and Installed?

The design and installation of geomembrane liners involve careful consideration of site-specific conditions and engineering requirements. Manufacturers tailor liners to project specifications, ensuring compatibility with site conditions and operational demands. Installation methods vary but commonly involve laying and welding panels together to create a continuous barrier. Quality control measures, including seam testing and thickness verification, are integral to ensuring the effectiveness and longevity of the liner system.

In conclusion, geomembrane liners represent a cornerstone of modern geosynthetics, providing sustainable solutions for environmental protection, resource management, and infrastructure development. Their versatility, durability, and cost-effectiveness make them indispensable in addressing the challenges of containment and environmental stewardship across various industries.

Comments

Post a Comment