Geocomposite Product Data: Key Insights for Geosynthetics Applications

In the geosynthetics industry, geocomposite product data plays a crucial role in selecting materials for various engineering applications. From drainage to soil stabilization, understanding this data helps optimize performance and longevity in infrastructure projects. Below, we address key questions about geocomposites and their importance.

What Are Geocomposites and How Do They Differ from Other Geosynthetics?

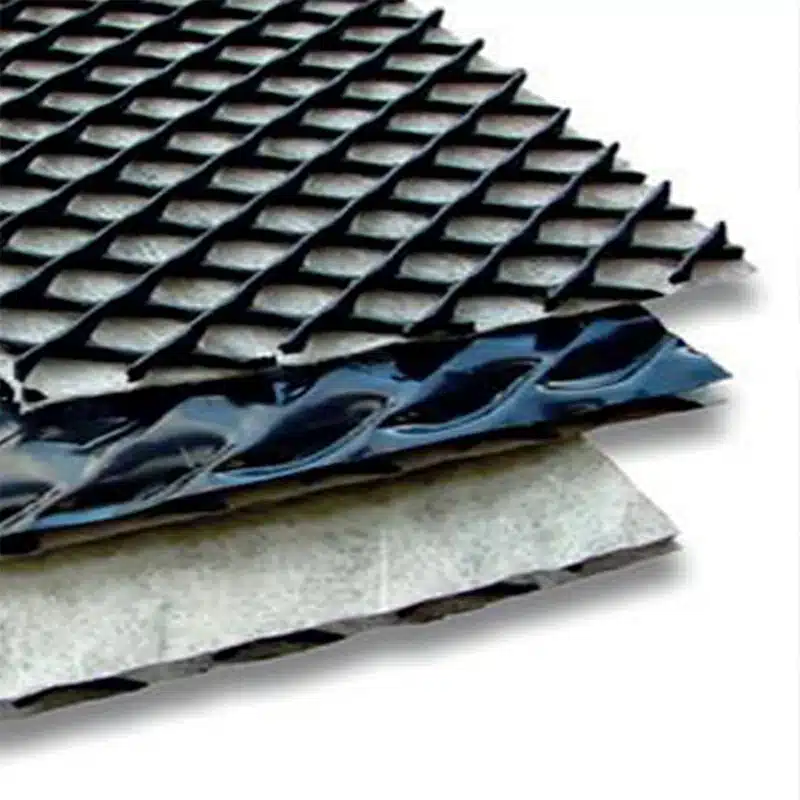

Geocomposites are multi-layered geosynthetic materials that combine different properties to enhance performance. Unlike geotextiles, geomembranes, or geogrids used individually, geocomposites integrate these materials to achieve superior drainage, filtration, reinforcement, or barrier functions.

For example, a common geocomposite consists of a geotextile bonded to a geonet, enhancing drainage capacity in landfill and road applications. According to the International Geosynthetics Society (IGS), geocomposites improve drainage efficiency by up to 40% compared to traditional granular drainage layers.

Why Is Geocomposite Product Data Important in Project Planning?

Engineers rely on geocomposite product data to ensure proper material selection based on factors such as permeability, tensile strength, and chemical resistance. These specifications impact the long-term stability and performance of geosynthetic applications.

A 2023 industry report by the Geosynthetic Institute (GSI) found that projects using geocomposites reduce installation costs by 25% while increasing structural stability by 30%. Such data allows engineers to make informed decisions that optimize both cost and efficiency.

What Are the Key Performance Indicators in Geocomposite Product Data?

When analyzing geocomposite product data, engineers focus on several critical indicators:

- Permeability: Determines fluid flow efficiency, essential for drainage applications.

- Tensile Strength: Ensures resistance against mechanical stress.

- Chemical Compatibility: Important for landfill and hazardous waste containment.

- Thickness & Weight: Affects ease of installation and load-bearing capacity.

According to a study by the American Society of Civil Engineers (ASCE), geocomposites with optimized permeability can extend roadway lifespan by up to 50%. These factors are crucial for ensuring long-term durability.

What Are the Latest Innovations in Geocomposite Technology?

The geosynthetics industry continues to evolve with advancements in material science and manufacturing. Some of the latest innovations include:

- Smart geocomposites with embedded sensors to monitor structural integrity in real-time.

- Biodegradable geocomposites for environmentally friendly applications.

- High-performance polymer coatings that improve resistance to harsh environmental conditions.

A recent market analysis by Research and Markets (2024) predicts a 6.2% annual growth rate in the geocomposite industry due to rising demand for sustainable infrastructure solutions.

Understanding geocomposite product data is essential for selecting the right materials and optimizing infrastructure performance. With growing demand and continuous innovation, geocomposites are shaping the future of geotechnical engineering. Engineers and project planners should leverage industry data to ensure efficiency, durability, and sustainability in their applications.

Comments

Post a Comment