Geonet Water Flow Direction — How Geonets Control Subsurface Flow for Reliable Drainage

Geonet water flow direction matters because the in-plane flow behavior of geonets and geocomposites determines how quickly and predictably you move water away from structures, slopes, and containment systems. Geonet water flow direction is therefore a design decision — not an afterthought.

What is “flow direction” in a geonet and why does it matter?

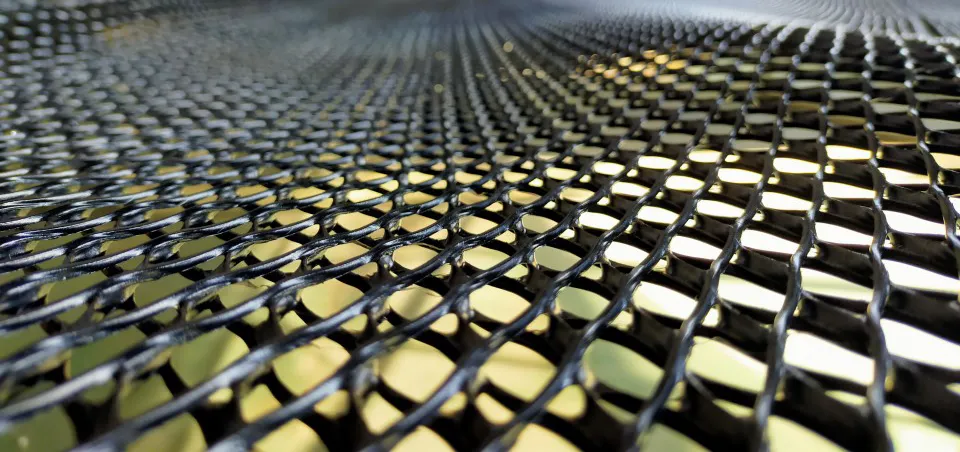

Flow direction refers to the principal in-plane paths that water takes through a geonet or geocomposite (the geonet core plus any facing geotextiles). Geonets are three-dimensional polymer cores (typically HDPE) that provide high in-plane transmissivity. Some geonets are biaxial (biplanar) and give strong lateral flow in two main directions; others are triplanar or have an oriented central rib that produces greater flow along one machine direction (MD) than across it (cross-direction, CD). Choosing the correct orientation — aligning the geonet’s intended flow direction parallel to the slope or toward the collector — maximizes drainage capacity and reduces pore-water pressures beneath loaded areas.For more on product structures, see the Geonet overview by GeoFanTex®.

How do you specify and install geonet so the water actually follows the intended direction?

Practical steps designers and installers use:

- Read the manufacturer’s datasheet for short-term in-plane flow (MD and CD transmissivity / k·s) and note which direction is the “machine” or primary flow direction. ASTM and industry tests (e.g., ASTM D4716) usually report MD and CD results.

- Orient rolls so the intended flow direction is aligned with the slope or drainage gradient (the machine direction typically parallel to the discharge path). Installation manuals explicitly state to lay rolls with the machine (intended flow) direction parallel to the slope. See the Drainage Geonet Installation Guide for best practices.

- When geotextiles are laminated to a geonet (geocomposite), ensure the filter fabric’s properties are compatible — the geotextile must allow flow into the geonet while preventing clogging and migration of fines. Refer to Geotextile products for filter options.

What performance differences matter: MD vs CD, biplanar vs triplanar?

MD vs CD: Many geonet products show higher transmissivity in the machine direction (MD). If a project relies on rapid along-slope conveyance, aligning MD to that direction can increase capacity. ASTM/industry test methods quantify these differences, so you should compare MD and CD transmissivity values on datasheets.

Biplanar vs triplanar: Biplanar geonets provide balanced lateral flow in two directions — useful for applications needing isotropic lateral drainage (e.g., many slopes, green roofs). Triplanar or ribbed designs concentrate flow more in one direction, increasing along-path capacity where flow is mostly unidirectional (e.g., long drainage strips). You can compare models via the HDPE Drainage Geonet product page.

How does accurate attention to geonet flow direction affect project risk, schedule and cost?

Correct orientation and product selection reduce the risk of pore-pressure build-up, slope instability, and costly rework. Compared to granular drains, geonets can reduce excavation volume, trucking of aggregates, and installation time — providing both schedule and lifecycle cost advantages. On the macro level, the geosynthetics industry is growing rapidly (driving wider adoption of engineered drainage solutions): global market estimates vary by source, for example USD 16,517.7 million in 2024, USD 19.49 billion in 2025, and global demand ≈ 7.9 billion m² in 2024 — each an indicator of expanding geosynthetic use in infrastructure (Grand View Research; Mordor Intelligence; Freedonia).

For technical datasheets and application examples, visit the Geofantex Drainage Geonet library.

In summary, geonet water flow direction plays a vital role in ensuring effective drainage and structural stability. Correctly aligning the geonet’s flow path with the slope or drainage line maximizes water transmissivity, reduces pore pressure, and enhances system durability. As the global geosynthetics market reached USD 16,517.7 million in 2024 (Grand View Research), industry focus on optimizing geonet water flow direction has become essen

Comments

Post a Comment