Geonet for Railways: Enhancing Track Stability and DrainageHow does a geonet improve railway performance?

The geonet for railways has become a critical solution in modern railway infrastructure. Geonets, a type of geosynthetic material provided by Geofantex, improve drainage, prevent subgrade saturation, and significantly extend trackbed life. By incorporating geonets, railway engineers can enhance track stability, reduce maintenance, and improve operational safety for high-speed and freight rail systems.

What is a geonet and why is it used in railway construction?

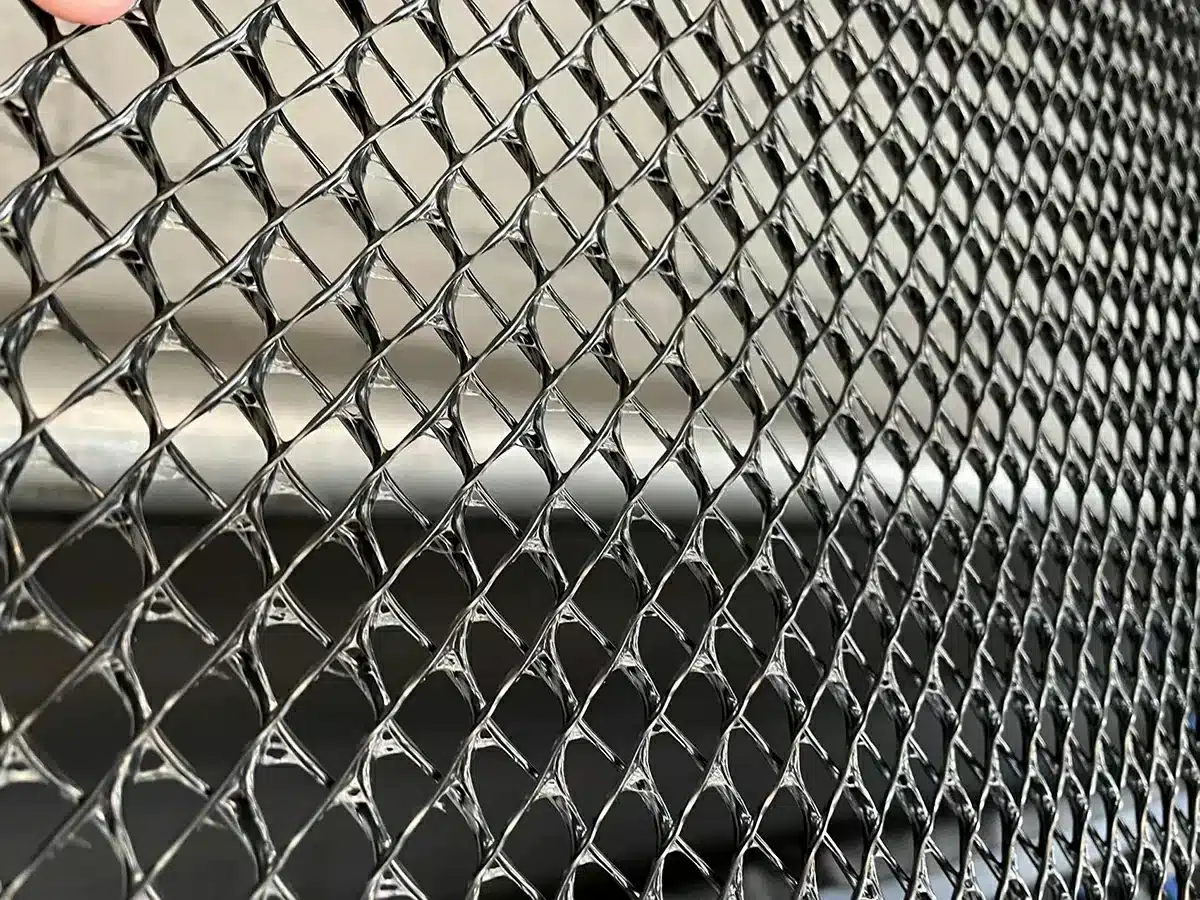

Geonets are three-dimensional, net-like geosynthetic materials, typically made from HDPE or polypropylene. In railway construction, a geonet for railways ensures in-plane drainage beneath ballast and subgrade layers. When combined with geotextile composites, geonets prevent soil and ballast mixing while allowing water to flow, reducing ballast fouling and maintaining uniform load distribution. Proper use of geonets helps minimize track settlement and enhances the overall durability of railway tracks.

How does a geonet improve railway performance?

The integration of a geonet for railways effectively removes water from under tracks, preventing subgrade saturation and reducing pore water pressure, which can cause settlement or track deformation. Geonets paired with geotextiles maintain separation between soil and ballast, improving load distribution and track stability. Properly installed geonets can increase ballast lifespan by up to 30% depending on traffic and soil conditions (International Journal of Railway Technology, 2023). Many railway projects now rely on Geofantex geonet solutions to maintain long-term track performance.

What are the industry trends and market data for geonets in railway applications?

The global geosynthetics market continues to grow, driven by rising infrastructure investment and the need for durable transport systems. In 2024, the market was valued at USD 13.5 billion and is projected to reach USD 21.1 billion by 2033 (IMARC Group, 2024). Geonets are increasingly adopted in railway construction to stabilize ballast, manage groundwater, and enhance track safety. High-speed rail and urban transit systems in Europe and Asia are incorporating geonets for improved drainage and subgrade protection, reflecting their growing significance in railway engineering. For effective solutions, engineers often turn to Geofantex geosynthetic products for railway applications.

What are best practices for implementing geonets in railways?

Geonets should be placed directly above the subgrade and beneath ballast layers to maximize drainage efficiency. Pairing geonets with the correct geotextile filtration layer prevents clogging while maintaining water flow. Installation must avoid folding, stretching, or misalignment, as errors can reduce drainage performance. Routine inspections and maintenance are recommended, especially in areas with heavy traffic or high rainfall, to ensure long-term effectiveness. Following guidelines from Geofantex installation manuals ensures geonets deliver optimal performance in railway projects.

The geonet for railways is a high-performance geosynthetic solution for modern railway infrastructure. It improves track drainage, stabilizes ballast, prevents subgrade saturation, and extends track life. By integrating geonets correctly, engineers can reduce maintenance costs, enhance safety, and achieve durable, long-lasting railway systems. Geofantex geosynthetic solutions provide reliable options for implementing geonets in various railway pro

Comments

Post a Comment