High Density Polyethylene Geomembrane: Reliable Solutions for Modern Environmental Projects

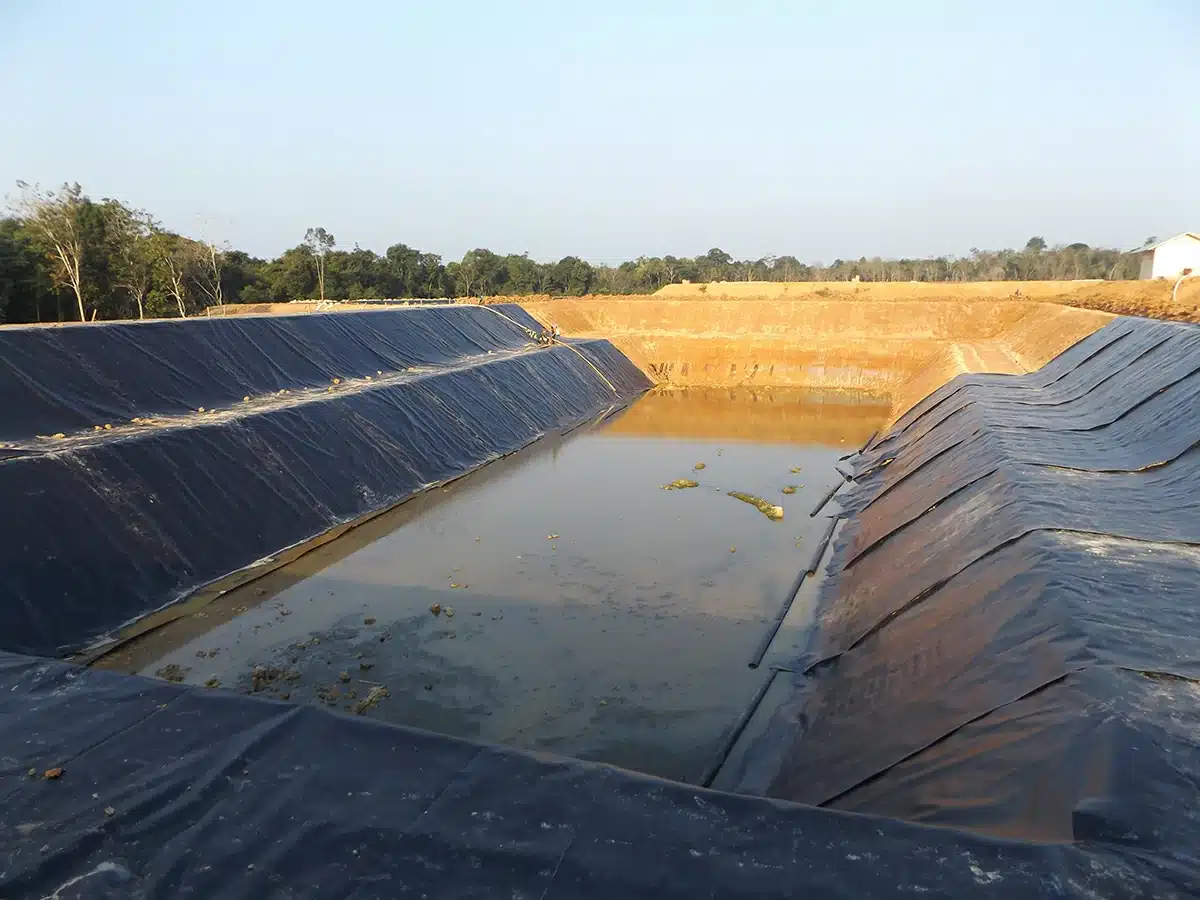

The use of high density polyethylene geomembrane is rapidly expanding as industries look for durable, cost-effective solutions for landfills, mining containment, and water management projects. Many contractors now prefer HDPE geomembrane liners to ensure long-term performance and regulatory compliance.

Expanding Demand in Environmental and Industrial Applications

With growing global focus on environmental protection, engineers and contractors are increasingly turning to high density polyethylene geomembrane products. Then, these geomembranes provide exceptional chemical resistance, long-term durability, and UV stability, making geosynthetic liners a preferred choice for modern projects.

Key Benefits Driving Market Adoption

Landfill liners, agricultural ponds, and industrial containment systems are top applications for geomembranes. Next, compared with traditional clay or concrete barriers, these high-quality liners reduce installation time, lower maintenance costs, and minimize leakage risks. Many projects now implement HDPE containment solutions for superior safety and efficiency.

Why Contractors Prefer Modern Geosynthetics

Manufacturers offer tailored thicknesses, textured surfaces, and certified quality testing, making it easy to select the right high density polyethylene geomembrane for any challenging environment. Finally, this combination of reliability and efficiency allows companies to complete projects faster while meeting environmental r

Comments

Post a Comment