Geonet for Landfill: Essential Insights for Waste Management Infrastructure

Effective drainage and liner protection are critical for modern landfill projects to ensure environmental safety and long-term operational stability. Geonet for landfill has become an essential geosynthetic solution, helping to channel leachate, reduce hydrostatic pressure, and prevent liner failures. As landfills grow in size and complexity worldwide, geonets provide a cost-effective and sustainable method to manage leachate and protect the surrounding environment. This article explores common questions about geonet for landfill, its benefits, market trends, and practical applications in waste management infrastructure.

What is geonet for landfill and how does it function?

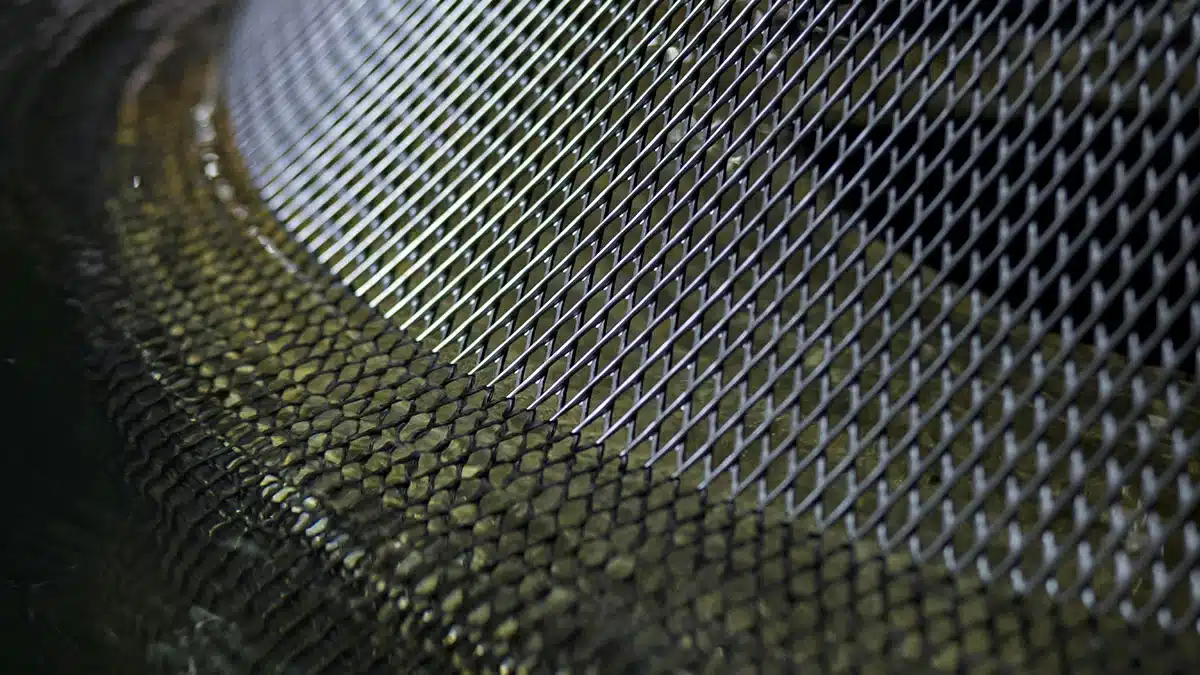

Geonet for landfill is a specialized geosynthetic material, typically made from high-density polyethylene (HDPE), designed to provide effective drainage and separation within landfill systems. It is installed between layers of waste, soil, and liner systems to channel leachate and prevent pore pressure buildup. By facilitating the controlled movement of liquids, geonets reduce the risk of liner failure and enhance overall landfill stability. For technical specifications and applications, you can refer to Geofantex geonet solutions.

Why is geonet for landfill important in modern waste management projects?

Geonet for landfill plays a vital role in ensuring environmental safety and operational efficiency of waste containment facilities. Landfills generate leachate and gas pressures that can compromise liner integrity. Geonets efficiently direct leachate to collection systems while maintaining separation between the liner and overlying layers. Studies show that using geonets can reduce liner maintenance costs by 15–25% (Source: Waste Management Journal). Learn more at Geofantex landfill solutions.

What does current industry data say about geonets in landfill applications?

The adoption of geosynthetics, particularly geonets, in waste management is growing worldwide. Landfill projects increasingly use geonets for drainage, leachate collection, and liner protection. Market analysis shows that the waste management sector accounts for approximately 35% of global geosynthetics usage (Source: World Geosynthetics Market Report, 2023). Landfills incorporating geonets report reductions in environmental incidents by 20–30% (Source: Environmental Protection Research Institute). Additional product details are available at Geofantex geosynthetics catalog.

What are the main benefits of specifying geonet for landfill in projects?

Specifying geonet for landfill provides multiple advantages for landfill design and long-term operation. Geonets allow rapid and uniform leachate drainage, protecting the liner and reducing hydrostatic pressure. They also reduce the need for thick granular layers, saving costs and installation time. HDPE geonets resist chemical attack and provide long-term durability. Industry studies show that geonets can increase liner lifespan by 15–20% (Source: Geosynthetics Institute). More applications can be found at Geofantex geonet applications.

Geonet for landfill is a vital geosynthetic solution for modern waste management, providing efficient leachate drainage, liner protection, and enhanced stability. Studies show geonets improve drainage efficiency by up to 60% (Source: International Journal of Geosynthetics and Ground Engineering) and reduce environmental incidents by 20–30% (Source: Environmental Protection Research Institute). With global landfill projects expanding, geonets remain a preferred material for safe, cost-effective, and sustainable waste management solutions. Learn more at Geof

Comments

Post a Comment