HDPE Pond Liner: Solving Seepage and Durability Problems in Geosynthetics Engineering

y used in geosynthetics engineering to solve critical issues such as water seepage, soil instability, and environmental contamination in ponds, reservoirs, and containment systems. By forming a continuous impermeable barrier, it helps ensure long-term water retention and structural safety.

What problem does HDPE pond liner solve in geosynthetics projects?

In geosynthetics applications, uncontrolled seepage is a major challenge that can lead to water loss, weakened subgrades, and slope instability. When water penetrates the soil, it accelerates erosion and increases maintenance risks. HDPE pond liner effectively blocks water migration, preserving soil integrity and maintaining stable pond structures over time.

Why is HDPE material preferred in geosynthetics systems?

HDPE material is valued for its extremely low permeability, excellent chemical resistance, and strong UV stability. These properties allow it to perform reliably under harsh environmental conditions and prolonged exposure. As a core waterproofing component, it integrates well with other geosynthetics solutions, improving overall system performance and durability. Leading manufacturers such as Geofantex support these applications with engineered materials designed for long-term containment use.

Where is HDPE pond liner commonly applied?

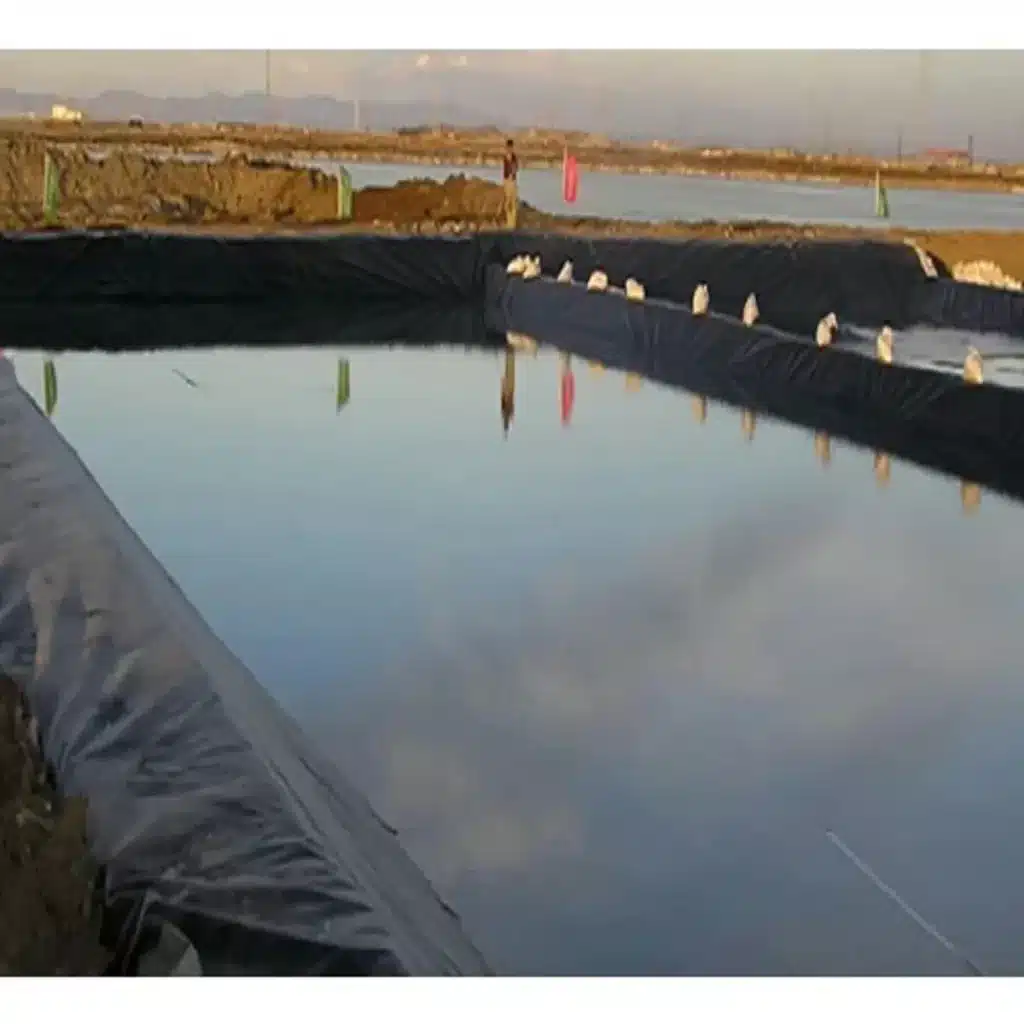

HDPE pond liner is commonly used in aquaculture ponds, agricultural irrigation reservoirs, landscape water features, and environmental containment projects such as wastewater ponds. Its adaptability to different site conditions makes it suitable for both small-scale and large-scale geosynthetics engineering projects.

How does HDPE pond liner reduce long-term project costs?

By preventing seepage and reducing water loss, the liner minimizes the need for frequent refilling and repair work. Its durability lowers maintenance requirements and extends the service life of the entire geosynthetics system. This results in improved cost efficiency, reduced environmental risk, and a higher return on investment throughout the project lifecycle.

This article explains how HDPE pond liner effectively solves seepage, soil instability, and environmental protection challenges in geosynthetics engineering. It highlights the material’s low permeability, strong chemical and UV resistance, and long service life, making it suitable for aquaculture, irrigation reservoirs, landscape ponds, and containment systems. Overall, HDPE pond liner provides a durable, cost-efficient solution that enhances structural stability and reduces long-term maintenance costs.

Comments

Post a Comment